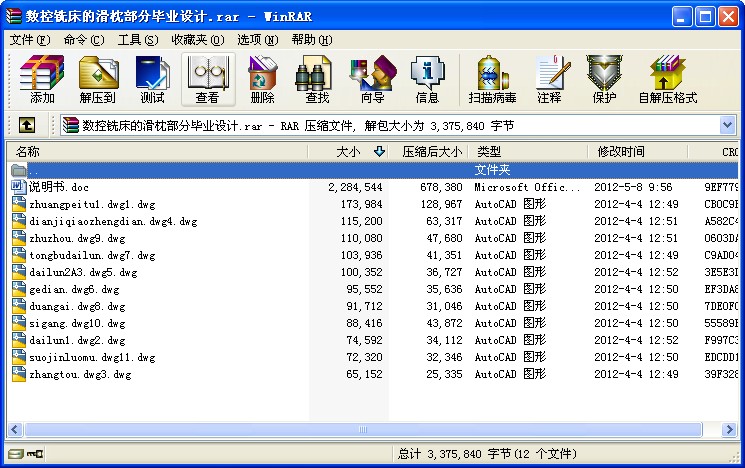

- 1МO№ыЧФ„УИҘЖӨҷC(jЁ©)ҷC(jЁ©)РөФO(shЁЁ)УӢ

- 2ТәБҰЧғҫШЖч

- 3CA6140ЬҮҙІЦчЭSПдФO(shЁЁ)УӢ3

- 4јҲәРіЙРНҷC(jЁ©)И«МЧ®…ҳI(yЁЁ)ФO(shЁЁ)УӢ

- 5ДzДТ”ө(shЁҙ)БЈҷC(jЁ©)ҲDјҲ

- 6Дк®a(chЁЈn)8500ҮҚИй·ЫОеҸҲCADҲDјҲ

- 7CM6132РНҫ«ГЬЬҮҙІЦчӮч„УПөҪy(tЁҜng)”ө(shЁҙ)ҝШёД

- 8ЖыЬҮөхЛюөхВДҺ§өхcadҲDјҜcadҲDјҲ

- 9ТәүәёЧХnіМФO(shЁЁ)УӢ(ә¬CADҲDјҲәНWORDХf

- 10Тәүәјф°еҷC(jЁ©)И«МЧ®…ҳI(yЁЁ)

”ө(shЁҙ)ҝШгҠҙІөД»¬ХнІҝ·Ц®…ҳI(yЁЁ)ФO(shЁЁ)УӢ

ОДҷnБфСФ №ІУР—lФuХ“

ёь¶а..ПВЭdЕЕРР

ёь¶а..ЧоРВОДҷn

- 1ХыМЧLS300ВЭРэЭ”ЛНҷC(jЁ©)ҲDјҲ CADҲDјҲ

- 2ұҪТТП©-ТТұҪҫ«рs№Ө¶О№ӨЛҮФO(shЁЁ)УӢcadҲD

- 3ОЭГжөхҷC(jЁ©)

- 416D303-2 іЈУГпL(fЁҘng)ҷC(jЁ©)ҝШЦЖлҠВ·ҲD

- 5DW201016-өЪ15ҶО-4ҳЗЯ^өАөШГжКҜІДј°

- 6ТЖ„Уіэүm

- 7Пы¶ҫ№©‘Ә(yЁ©ng)ЦРРДҲDјҲ

- 8г@ҝЧҪMәПҷC(jЁ©)ҙІФO(shЁЁ)УӢИ«МЧҝӮСbcadҲDјҲФO(shЁЁ)

- 9г@ҷC(jЁ©)ЭoЦъ№ӨҫЯФO(shЁЁ)УӢДЈРН

- 10г@—UВ©ҙЕҷzңyҷC(jЁ©)РөІҝ·ЦФO(shЁЁ)УӢИ«МЧcadҲD

ҹбйTОДҷn

- 1”ө(shЁҙ)ҝШҷC(jЁ©)ҙІЙППВБПҷC(jЁ©)РөКЦФO(shЁЁ)УӢ

- 2»ЁЙъИҘҡӨҷC(jЁ©)ФO(shЁЁ)УӢ

- 3МO№ыЧФ„УИҘЖӨҷC(jЁ©)ҷC(jЁ©)РөФO(shЁЁ)УӢ

- 4јӨ№вЗРёоҷC(jЁ©)ҲD(°ьә¬cadҲDјҲ+ХfГч•ш)

- 5ТЖ„Уіэүm

- 6јҲәРіЙРНҷC(jЁ©)И«МЧ®…ҳI(yЁЁ)ФO(shЁЁ)УӢ

- 7г@ҝЧҪMәПҷC(jЁ©)ҙІФO(shЁЁ)УӢИ«МЧҝӮСbcadҲDјҲФO(shЁЁ)

- 8ТәүәҷC(jЁ©)РөКЦЈЁ®…ҳI(yЁЁ)ФO(shЁЁ)УӢЈ©

- 9РВРНУсГЧГ“БЈҷC(jЁ©)ФO(shЁЁ)УӢ3DДЈРНsldprtИэ

- 10ЧФ„УЗР№ЬҷC(jЁ©)ј°ЛНБПҷC(jЁ©)ҳӢ(gЁ°u)ФO(shЁЁ)УӢ(И«МЧФO(shЁЁ)УӢ

ҹбйTкP(guЁЎn)жIФ~Јә

ҹбйTкP(guЁЎn)жIФ~Јә

ФҘ№«ҫW(wЁЈng)°ІӮд 41072402000322М–

ФҘ№«ҫW(wЁЈng)°ІӮд 41072402000322М–